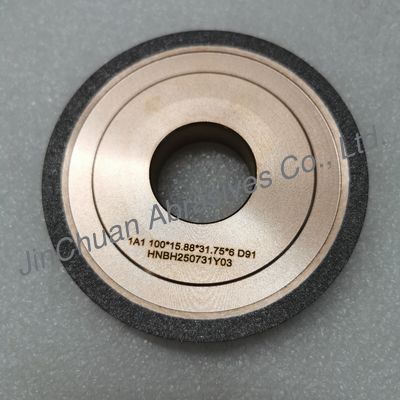

Product Description:

Hybrid grinding wheels are made of a resin-metal hybrid binder, offering superior grinding performance and retention. They are currently widely used for mass production of cemented carbide and high-speed steel tools.

This hybrid structure enables efficient grinding of hard and brittle materials (such as carbide, ceramics, glass, and tungsten carbide), as well as challenging steels (such as high-speed steel, tool steel, and stainless steel) and some metal composites. Its excellent chip evacuation and cooling properties reduce friction during grinding, resulting in less grinding heat and helping to prevent workpiece burns, microcracks, and metallographic changes. It is particularly well-suited for precision and ultra-precision machining.

Features:

- Mixed bond

- Widely applicable

- High grinding ratio

- High grinding ratio

- Willfulness and flexibility

- Very long lifespan

- Very good self-sharpening

- Excellent surface quality

Technical Parameters:

| Material |

Diamond |

| Package |

cardboard box |

| Thickness |

10mm |

| Base Body |

Resin + Metal Bond |

| Profile |

High-quality grinding |

| Grit Size |

D64 |

| Country Of Origin |

China |

| Packing |

Standard Exported Carton Packing |

| Hs Code |

6804211000 |

| Application |

High-end precision manufacturing |

Applications:

Hybrit diamond grinding wheels, due to their superior performance, are widely used in applications requiring high precision, high efficiency, and long life:

Carbide tool grinding: Sharpening and flute grinding of milling cutters, drills, reamers, and taps.

Aerospace and automotive industries: Grinding precision components made of high-temperature alloys and composite materials, such as engine parts, turbine blades, and fuel injectors.

Cutting tool manufacturing: Essential tools for manufacturing PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride) tools.

Precision component machining: Precision grinding of carbide or ceramic parts, such as bearings, guide rails, and seal rings.

Semiconductor and optical industries: Machining of sapphire substrates, silicon crystals, and optical glass.

Dressing: Use specialized dressing tools (such as diamond dressing rollers or dressing pens) to restore the correct geometry of the grinding wheel.

Dressing: Hybrit grinding wheels are generally self-sharpening, but they may require periodic sharpening to optimize grinding performance. A common method is to use a SiC stick or a specialized dressing paste for manual or machine sharpening. This removes grinding debris from the bond surface and helps expose new abrasive grains.

Coolant: Using high-quality, thoroughly filtered coolant is highly recommended. Adequate coolant not only removes heat but also flushes away grinding debris, preventing wheel clogging and maximizing the performance of the Hybrit grinding wheel.

Our company

Zhengzhou Jinchuan abrasive abrasive co., LTD. Is committed to providing the most advanced diamond and cubic boron nitride products.We have experienced engineers and technical experts, professional industrial knowledge and technical services to help customers find the best solutions. If you have specific processing requirements, please contact us directly. We can provide the most suitable Hybrit product model and processing parameter recommendations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!