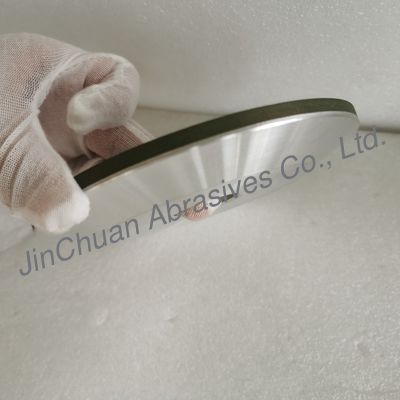

4A2 Resin Bond Doamond Grinding Wheel Product Description

Product Name: Resin Bond Diamond Grinding Wheel

Product Overview:

Resin diamond grinding wheel is a high-performance grinding tool with resin as the binder and diamond abrasive as the cutting body. It combines the ultra-high hardness of diamond and the flexibility of resin binder, and is suitable for high-precision and high-efficiency processing of hard and brittle materials such as ceramics, glass, semiconductors, and cemented carbide.

Product Features:

High grinding efficiency: Diamond has an extremely high hardness (Mohs hardness 10), which can quickly remove hard and brittle materials.

Good self-sharpening: Resin binders wear moderately, which can continuously expose new abrasive grains and maintain sharpness.

Low grinding temperature: Resin has poor thermal conductivity, but thermal damage can be reduced through pores or coolant.

High surface quality: Suitable for precision machining, reducing chipping or cracks on the workpiece.

Lightweight design: Resin has low density and is suitable for high-speed grinding.

Product size(mm):

| Diameter(D) |

Thickness(T) |

Inner hole(H) |

Abrasive width(W) |

Abrasive depth(X) |

Granularity |

| 150 |

15 |

32 |

6 |

5 |

D500# |

Of course if you need other sizes , we can customize for you.

Application:

Cemented carbide: sharpening and polishing of cutting tools and molds.

Ceramics/glass: precision processing of mobile phone covers and optical lenses.

Semiconductor materials: cutting and grinding of silicon wafers and silicon carbide wafers.

Stone processing: shaping and polishing of marble and granite.

Packaging and Shipping:

Each CBN grinding wheel is carefully packed in a sealed bag and wrapped with bubble film to prevent scratches or damage during transportation. After packaging, it is placed in a carton and sealed securely with tape. All orders are shipped via reliable couriers. After the order is shipped, we will provide customers with tracking information and estimated delivery time.

Competitive Advantages

1.We offer high quality products at competitive price.

2. Shortest delivery time.

3. Flexible payment terms.

4. Timely after-sale service.

5. Most of our equipment can be replaceable with international brands.

6. Our products have been exported to Argentina, Egypt, US, Australia, Romania, Pakistan, Dubai, Abu Dhabi, Iran, India,

Indonesia, Vietnam, Malaysia and many other countries.

If you need to customize, please provide the following information:

1. Dimensions, including outer diameter, aperture, thickness, width and thickness of abrasive layer;

2. Abrasive, abrasive sand particle and concentration;

3. Wheel application;

4. Pictures and drawings of wheels;

We can then design and quote for you

suggestion:

The selection of resin diamond grinding wheels requires comprehensive consideration of material properties, processing accuracy and cost. It is recommended that you communicate with us about specific parameters such as workpiece material, grinding amount, and equipment conditions to match the best solution.

Looking forward to your inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!