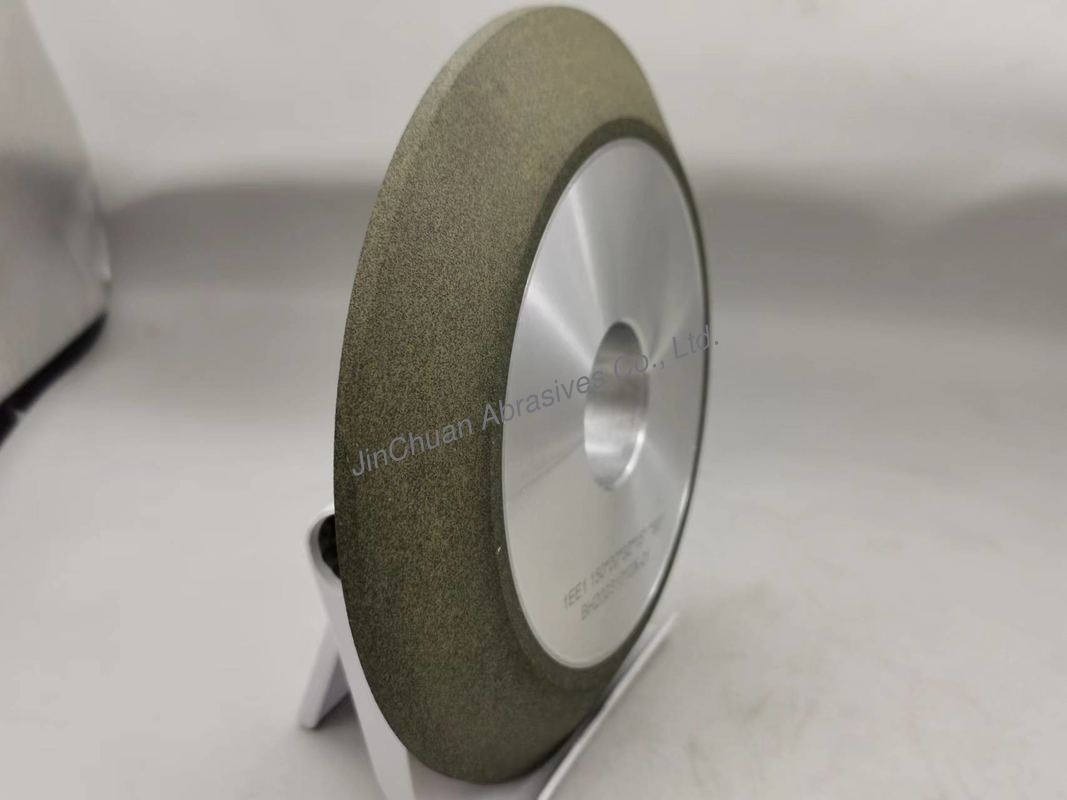

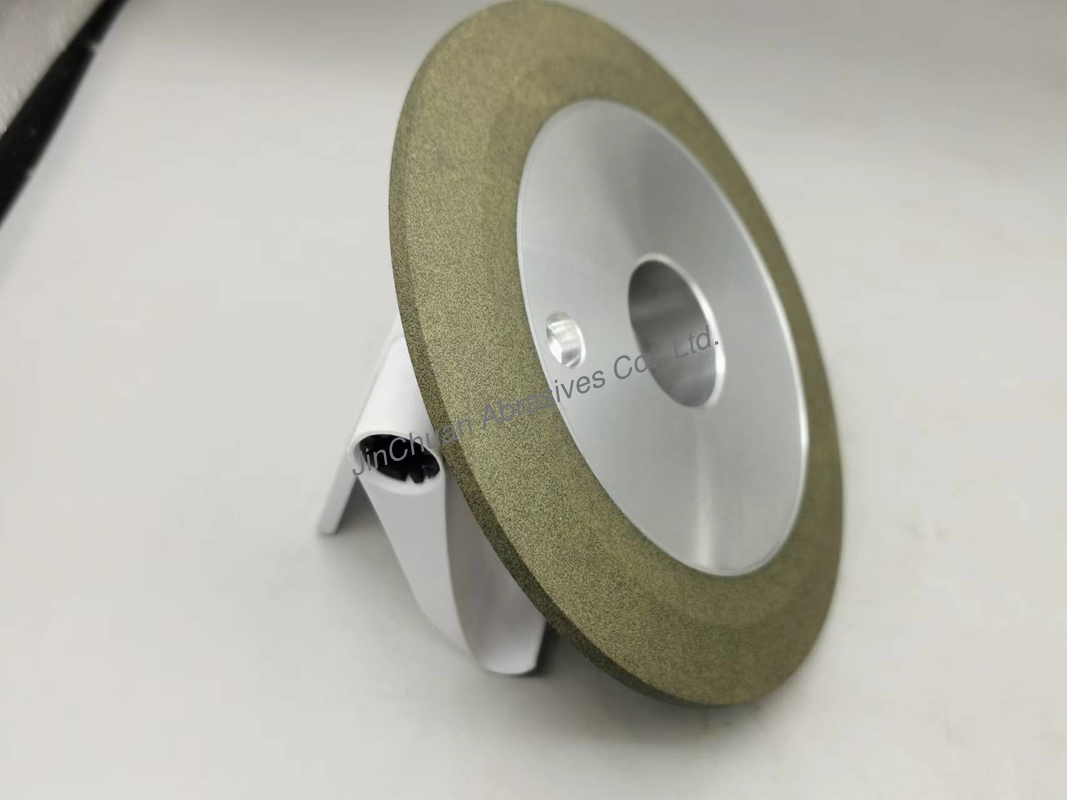

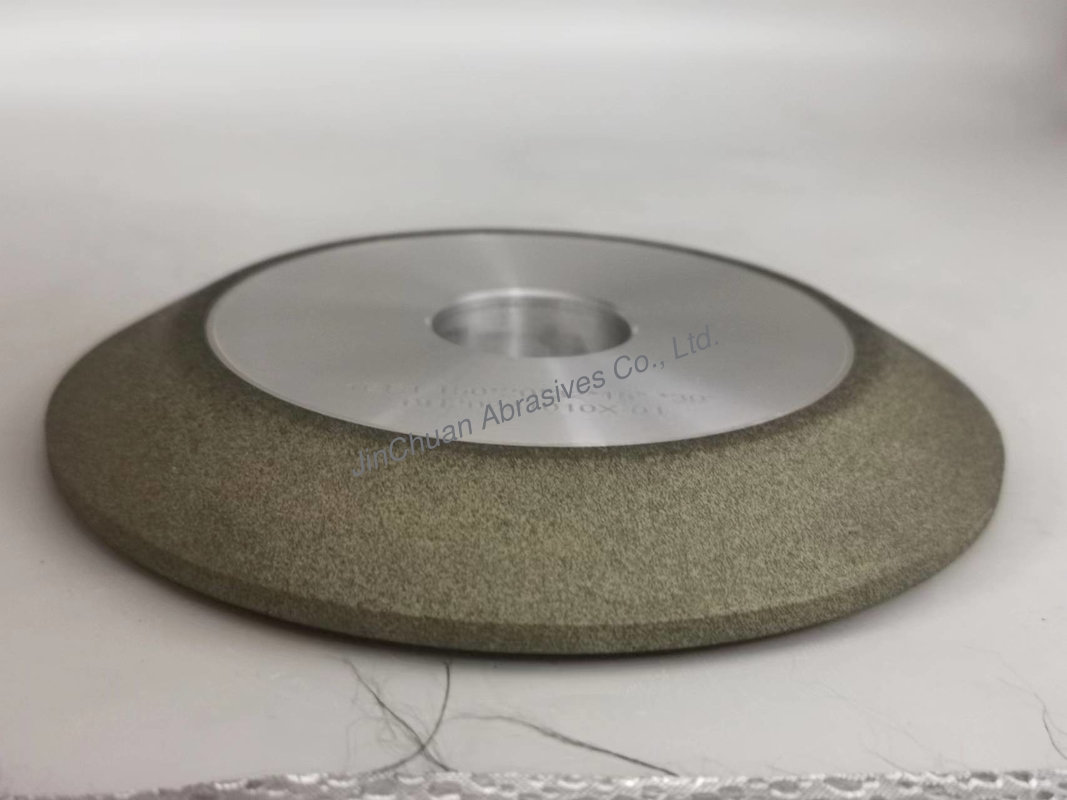

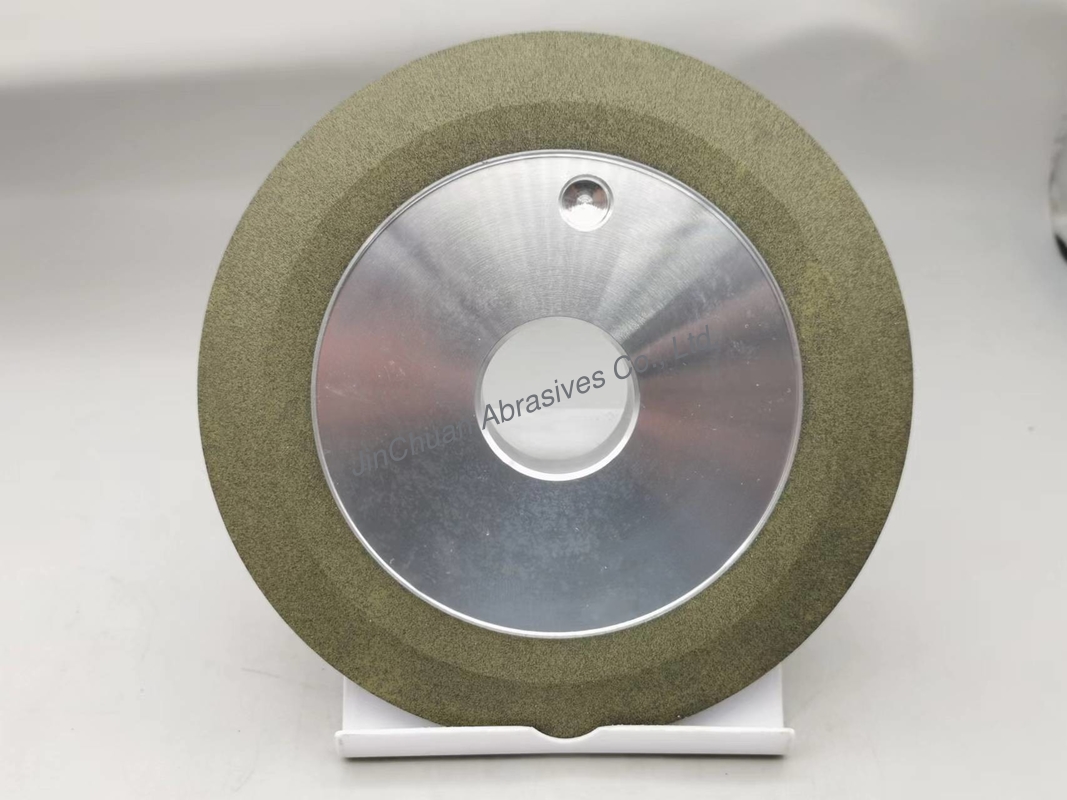

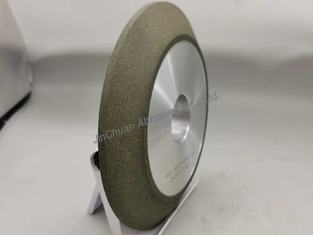

1EE1 Cylindrical Resin Grinding Wheel As Edge Cutting Grinding Wheel 100mm

-

Highlight

Resin Grinding Wheel 100mm

,Cylindrical Resin Grinding Wheel

,1EE1 Resin Bond Grinding Wheel

-

PackageCarton Box

-

Wheel Size150*20*32*V30*V15 B181

-

Concentration100%

-

ColourGray

-

AbrasivesCBN B181

-

DeliveryBy Express

-

Place of OriginChina

-

Brand NameJC

-

CertificationISO

-

Model Number1EE1

-

Minimum Order Quantity5

-

PriceNegotiable

-

Packaging DetailsWooden box

-

Delivery Time5-8 work days

-

Payment TermsT/T

-

Supply Ability1000/month

1EE1 Cylindrical Resin Grinding Wheel As Edge Cutting Grinding Wheel 100mm

1EE1 Resin Grinding Wheel For Cylindrical Grinding As Edge Cutting Grinding Wheel 100mm

Cubic boron nitride (CBN) grinding wheel is suitable for processing the following products:

1.high manganese steel;

2. high chromium, nickel, molybdenum alloy steel;

3.chilled cast iron (HS80~90);

4.all kinds of hardened steel ( HRC55~65);

5.All kinds of cast iron (HB200~400), etc., and have been used in domestic automobiles (gears, flywheels, shafts, bearings, etc.),

rollers, slurry pumps (impellers, volutes, guard plates, sheaths, etc. machining), molds, cylinder liners;

| Size | Diameter | Thickness | Inner hole | Grit Size |

| 150mm | 20mm | 32mm |

B181

|

Our Advantages

1. High grinding efficiency, relatively slow grinding wheel consumption and long grinding life.

2. Short production cycle, high removal rate and easy formation of complex surface.

3. Certain elasticity, which is conducive to improving the roughness of the workpiece surface, and is mainly used for fine grinding, semi-fine grinding, knife grinding, polishing and other processes.

4. Our company has professional technologies and equipment’s, which can form resin diamond grinding wheels with various complex surfaces.

Applications

Mainly used for grinding high-hard alloys, non-metallic materials, cutting hard and brittle hard alloys, non-metallic minerals, etc. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials and wear-resistant cast iron, stone, etc.Specially used to all kinds of sbrssives machine

![]()

If you need to customize, please provide the following information:

1. Dimensions, including outer diameter, aperture, thickness, width and thickness of abrasive layer;

2. Abrasive, abrasive sand particle and concentration;

3. Adhesive;

4. Wheel application;

5. Pictures and drawings of wheels;

We can then design and quote for you