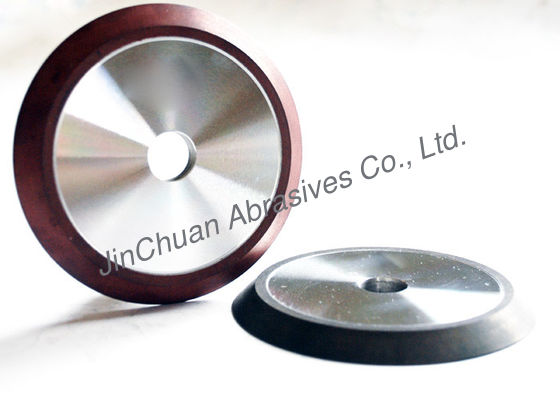

Resion Diamond Grinding Wheel Used To Abrasive Hard Metal Material

Paralell Resin Diamond Grinding Wheel Yellow Colour

Specifaction

350mm*40mm*101.6mm*10mm

Resin bond grinding wheels have characteristics of good self-sharpening, high grindingefficiency, low grinding heat and no loading.

Resin bond is a kind of organic bond. The grinding wheel made by this bond has high strength, certain elasticity, low heat resistance, good self-sharpening, easy to make and short process cycle.It can manufacture grinding wheels and very thin grinding wheels with working speed over 50 m/s.Its application range is second only to ceramic binder, widely used in rough grinding, rough grinding, cutting and free grinding, such as grinding ingots, casting burring and so on.It can manufacture high speed and high finish grinding wheel, heavy load grinding wheel, cutting wheel and all kinds of special requirements.

These wheels are especially suitable for grinding hard alloy tools such as saws, cutting machines, drilling tools, end mills, etc.In addition, these tools can be used for precision grinding of carbide dies, rollers and carbonized wear parts.Resin bonded grinding wheel is the first choice for precision machining of ceramic products and thermal spraying layer of tungsten carbide and ceramic products.Resin-bonded grinding wheels can also be used in conjunction with CBN for the grinding of high speed steel, tool and die steel and over FtRC50 super heat resistant alloys.

We have different models, which can be made to order according to different sizes

Applications

1,Specially used to all kinds of sbrssives machine

2,Can customized it according to customs request

3, as we are manufacturer of diamond powders which is raw material of diamond tools, we can assure the quality from original material. And can control the quality of all our tools as we have a professional and strict QC team.

4,as a manufacturer, we can save production cost for customer.

5,we have professional sales team and engineering team, can reply you at the first time, and solve problems for you soon.

Production Features

The Wheels Are made of high quality diamond and specially modified resin

The most advanced production equipment and art

Advantage

1,Excellent surface roughness and flatness

2,High processing speed working fast

3,Used to big power machine

4,Long durable

5,High production equipment

6,Long duarble ,it is three times life than normal wheel

7,Out Of Shap not easy

8,We can make 2000 to 5000 Pcs of wheels one month,

9,We can customize it if u provide us drawing

| D |

T |

GRIT |

RPM |

| 101.3 |

0.89 |

100 |

4700 |

| 127 |

0.89 |

100 |

4500 |

| 152.4 |

0.89 |

100 |

4300 |

| 152.4 |

1.14 |

100 |

4300 |

| 152.4 |

1.14 |

120 |

4300 |

| 203.2 |

1.14 |

120 |

3700 |

| 254 |

1.27 |

100 |

3000 |

Company profile

Zhengzhou Jinchuan abrasive abrasive co., LTD. Is committed to providing the most advanced diamond and cubic boron nitride products.

We have experienced engineers and technical experts, professional industrial knowledge and technical services to help customers find the best solutions.

Our sophisticated production equipment and advanced testing equipment, so that our products good performance.Constantly pursue new technology and continuous improvement.

We look forward to our cooperation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!