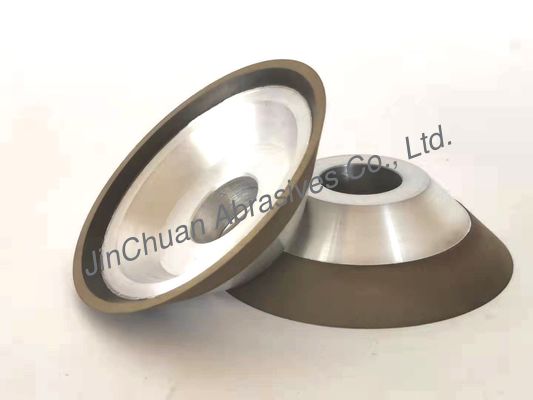

12V9 75D*20T/3X/12U/10E/20H SD64 ,Resin grinding wheel,Grinding wheel, diamond whell,brown,Good quality.

| Product name |

12V9 |

| Product description |

75D*20T/3X/12U/10E/20H SD64 |

| Product usage |

Sharpened woodworking knife |

Resin grinding wheel,Grinding wheel, diamond whell,brown,Good quality.

The resin grinding wheel is a grinding wheel made of resin, such as phenolic, epoxy, polyurethane, polyvinyl alcohol, etc.; the resin grinding wheel has high strength, and can add reinforcing fiber mesh and steel bar in the grinding wheel, such as cutting piece and grinding piece, most of us The resin grinding wheel is not waterproof, it can not be ground with grinding fluid.

Of course, there are some resin grinding wheels that need to be added with grinding fluid grinding.

For example, epoxy, resin grinding wheel has good grinding finish, the workpiece is not easy to burn, and the resin grinding wheel is used for cutting. Sheet, double end, heavy duty grinding wheel, polishing wheel, etc., resin bond grinding wheel is lower in strength than metal bond and ceramic bond.

Installation needs

The grinding wheel must be carefully inspected and identified before installation. The steps to check the authentication are:

1. Check if the grade of the grinding wheel is correct and whether it meets the performance, shape and size of all selected grinding wheels.

2. Check and identify the appearance of the grinding wheel. Use your eyes to see if the wheel is damaged (or has cracks). A grinding wheel with a damaged appearance (or a crack) cannot be used. In addition, there is a requirement that both ends of the grinding wheel be flat and there must be no obvious skew.

3. Inspect and identify the internal crack of the grinding wheel. With a hand-held grinding wheel, tap the grinding wheel with a wooden hammer to hear the sound. The cracked wheel gives a crisp sound, and the cracked grinding wheel is hoarse, which cannot be used.

Characteristics:

1.The resin binder is an organic binder, and the binder has a high strength

2.Have a certain flexibility

3.Low heat resistance

4.Short process cycle

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!