Product Description:

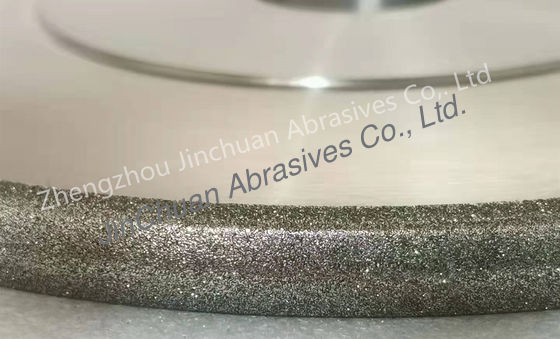

Diamond grinding wheels are one of the most typical tools in superhard material tools. They are products with specific shapes, properties, and uses, made from diamond as the abrasive and with the help of bonding agents or other auxiliary materials under certain production conditions. Diamond grinding wheels can be mainly classified according to the type of bonding agent: metal-bonded, ceramic-bonded, and resin-bonded. With the development of superhard material tool technology, the objects it can process almost encompass all known materials, greatly improving the processing efficiency and quality in various precision machining fields. Especially as an important component of advanced manufacturing technologies such as high-speed, precision, CNC, and micro-machining, its applications are mainly in two major areas: one is the processing of hard and brittle materials, mainly referring to the processing of hard and brittle materials such as sapphire, single-crystal silicon, polycrystalline silicon, magnetic materials, silicon carbide, refractory materials, glass, and geological drilling; the other is various precision machining fields, mainly referring to precision machining fields such as electronics, machinery, automobiles, and new energy. According to their different uses, they can be further divided into several major categories: diamond grinding wheels, diamond sawing wheels, diamond drilling tips, etc.

| size |

200mm*10mm*32mm |

| Usage |

Polish the carbide Head |

| Grit |

D181 |

| Abrasive |

diamond |

| specifications |

Can be customized |

| packaging |

cartons |

| transport |

International express |

Product feature:

Diamond grinding wheel is an ideal tool for grinding hard alloy materials.with high quality diamond, mature electroplating process and advanced technology formula, the product quality is stable and reliable, and the grinding efficiency is high.

Metal bond (code J), mainly used for making diamond grinding wheel.

The characteristics of the bronze bonded diamond grinding wheel are good shape, high strength and toughness.

The bronze grinding wheel made of metal bond with various proportions has good static balance and excellent grinding effect, which is an ideal choice.

Advantage:

(1)Good abrasive property, good wear resistance, good abrasive holding force, long life of grinding wheel

(2)In the hard alloy head, grinding out the effect is better, forming faster

(3)High rotation of grinding wheel, high precision, better fit for grinding

(4)Strong applicability, polished out of the product is relatively smooth, basically no defects

Use:

Parallel grinding: mainly used for cylindrical grinding and machining of hard alloy edges

Parallel arc grinding wheel: mainly used for hard alloy grinding and arc surface grinding

Concave and double face grinding wheel, mainly used for grinding measuring tools and coreless grinding machines

Company profile

Our factory founded in 2007, our company is a professional manufacturer and exporter of industrial brushes and knives.We have strong r & d capabilities and sound quality management.We can produce special products according to your requirements to meet your different needs.We provide you with reliable quality and competitive factory prices to establish long-term cooperation, welcome to contact us at any time!

Please contact me if you have any questions. Looking forward to our cooperation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!