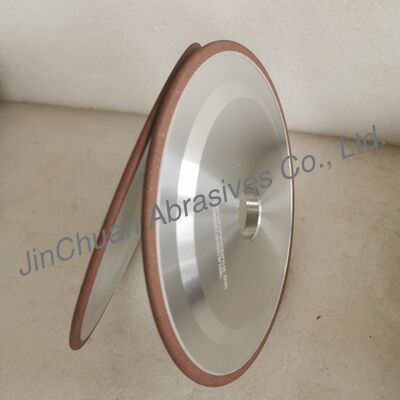

Product Description:

Resin-bonded diamond grinding wheels are precision diamond tools specifically designed for wet grinding processes. They are made from diamond abrasive particles and a resin binder, and feature high efficiency, self-sharpening properties, and excellent elasticity. These grinding wheels offer high grinding efficiency, low heat generation, and resistance to clogging, and are capable of processing workpieces with complex shapes. They are widely used in the precision grinding, polishing, and shaping of hard and brittle materials such as cemented carbide, ceramics, and glass. They are an ideal choice for achieving high-precision surface finishes and complex contour machining, especially in the fields of precision tool manufacturing and complex surface processing.

Diamond resin grinding wheels are composed of diamond abrasive, resin binder, and auxiliary materials. The abrasive material uses synthetic diamond particles with a grit size range from 80# to 3000#. The binder is primarily phenolic resin, with fillers such as silicon carbide powder and fluorite powder added to enhance performance. Some products incorporate a fiberglass mesh as a reinforcing layer, and the grinding efficiency and tool life are balanced by optimizing the abrasive volume concentration.

Resin diamond grinding wheels are indispensable tools in modern precision machining. Thanks to their ultra-hard materials and advanced resin technology, they play a crucial role in the processing of hard materials where high precision, high efficiency, and durability are required.Choose our diamond grinding wheels for industrial blade sharpening machines to experience the ultimate sharpening precision and efficiency. Upgrade your sharpening process with our high-quality wheels and achieve superior results with every use.

Features:

1. Self-sharpening and heat dissipation: Abrasive particles automatically detach after wear, maintaining sharpness, and the grinding zone temperature is reduced by 40% compared to metal grinding wheels.

2. Elastic matrix: The resin binder provides elastic deformation capabilities, allowing for workpiece surface roughness as low as Ra 0.1 μm.

3. Complex surface machining: The fluidity of the resin allows for the formation of irregularly shaped contours, including double bevels and concave curved surfaces.

4. Wear resistance enhancement: Tungsten carbide brazing technology improves abrasive particle retention, extending tool life to 1.8 times that of ceramic grinding wheels.

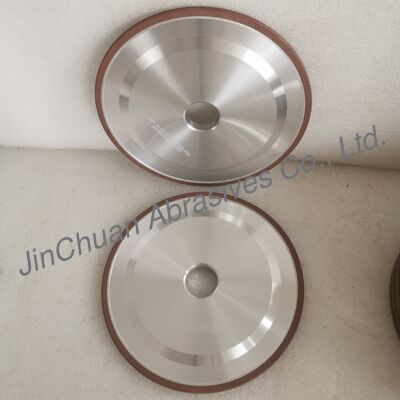

Technical Parameters:

| Material |

Aluminum |

| Abrasive layer |

Diamond |

| Diameter |

200mm |

| Package |

One in paperbox |

| Delivery time |

7 working days |

| Grit Size |

D181 |

| Country Of Origin |

China |

| Application |

For Cemented Carbide |

| Thickness |

10mm |

| Innor hole |

20mm |

| Abrasive width |

6mm |

| Abrasive hight |

4mm |

| Concentration |

C100 |

Q&A:

1, Do you have samples?

We provide samples so you can test our products first. We prioritize product quality to ensure a long-term partnership in the future.

2, Do you have these in stock?

Most of our products are custom-made according to customer specifications and dimensions; we only stock standard sizes.

3. What payment methods do you offer?

We offer flexible payment methods including T/T, L/C, Western Union and PayPal.

4, What are your shipping methods?

UPS, DHL, Fedex, EMS etc. 7-10 days for delivery. Of course, we also offer sea freight.

5.What is your delivery time?

For standard products that are in stock, we can ship immediately after the customer makes the payment.

For customized products, the delivery time is generally 7-10 days.

Looking forward to your inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!