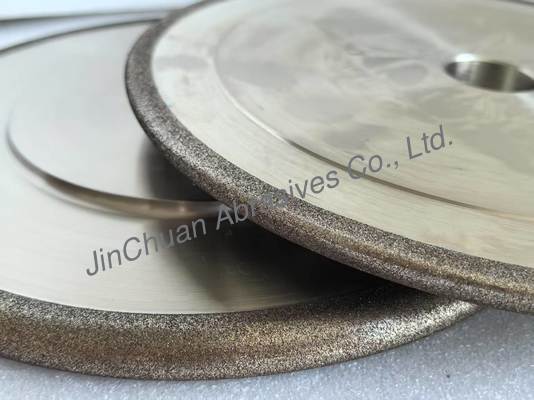

Electro CBN Grinding Wheels For Consistent Performance And Long Lifespan Sharpening Disc

Product Information Of Electroplated CBN wheel for grinding and sharpening

Electroplated Cubic Boron Nitride (CBN) grinding and sharpening wheels are high-performance abrasive tools designed for precision grinding of very hard materials.

A **single layer** of high-quality CBN abrasive grains is **electrochemically bonded** (plated) onto a precision-made metal core (usually steel or aluminum).

* This creates a wheel with the abrasive grains held firmly at their bases, leaving their sharp cutting edges fully exposed.

Main Data Of Electroplated diamond grinding and sharpening wheels

| Technical Parameter |

Details |

| Size |

250*14*32*10mm |

| Hs Code |

6804211000 |

| Base Body |

Steel |

| Shape |

flat |

| Material |

CBN, Steel Basebody |

| Packing |

Standard Exported Carton Packing |

| Package |

Color Box |

| Country Of Origin |

China |

| Application |

Grinding and Sharpening

|

Advantages:

1. **Extreme Hardness & Wear Resistance:** CBN is the second hardest known material (after diamond), making these wheels exceptionally durable and long-lasting, especially when grinding ferrous materials (where diamond would rapidly degrade).

2. **High Abrasive Exposure:** The single-layer, electroplated bond exposes a very high percentage of each grain. This results in:

* **Free Cutting Action:** Reduced cutting forces and less tendency to "glaze."

* **Excellent Coolant Access:** Efficient heat removal at the cutting zone.

* **High Material Removal Rates (MRR):** Especially for light to moderate stock removal.

* **Superior Surface Finish:** Achievable due to sharp, consistent cutting.

* **Minimal Heat Generation:** Critical for preventing workpiece burn, temper loss, or metallurgical damage.

3. **Long Wheel Life:** Due to CBN's hardness and wear resistance, these wheels last significantly longer than conventional abrasive wheels (like AlOx or SiC) or even resin-bonded CBN wheels on suitable applications.

4. **Form Holding:** Ideal for grinding complex profiles and maintaining sharp edges (like in sharpening) because the grains don't fracture or wear significantly during grinding. The wheel profile remains stable until the grains are completely worn or pulled out.

5. **No Dressing Required:** Electroplated wheels come ready to use and **cannot be dressed or trued** in the conventional sense. This eliminates downtime for dressing but means the wheel must be discarded once worn.

6. **High Grinding Speeds:** Can operate at high peripheral speeds (often 80-160 m/s), increasing productivity and often improving surface finish.

7. **Versatility in Forms:** Can be manufactured in a wide variety of complex shapes, profiles, and small diameters (e.g., points, cones, cylinders, custom forms) due to the plating process.

FAQ:

1.What material does your product use ?

Our product abrasives are diamond or CBN , which are electroplated, resin, vitrified, or metal bonded.

2.Do you offer samples ?

Yes, In order to start the new and happy cooperation , we can provide our customers sample for testing at the first order , we believe that you will be satisified with our product quality.

3. Can we go to visit your factory ?

Of course yes , welcome to visit our factory , you can see our production capacity and technoly. Remeber to contact our sales first before your visit.

4.How can you guarantee the quality ?

We examine the quality 3 times before strat the delivery , first : pre-production , second : post-production , third : before delivery . So do not worry about this.

NOTE: If you do not find the product you want in this website, contact us first, we can design and produce any specification of grinding wheels as customer's requirement.

If you need to customize, please provide the following information:

1. Dimensions, including outer diameter, aperture, thickness, width and thickness of abrasive layer;

2. Abrasive, abrasive sand particle and concentration;

3. Adhesive;

4. Wheel application;

5. Pictures and drawings of wheels;

We can then design and quote for you

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!