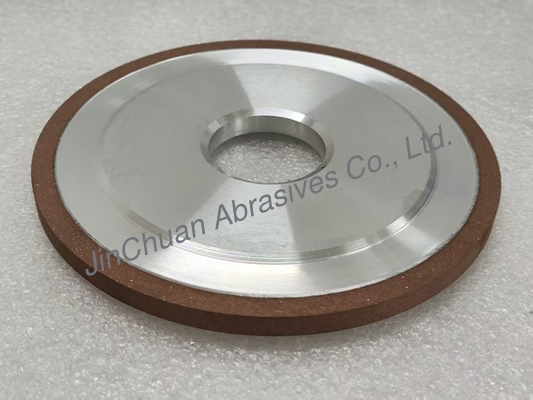

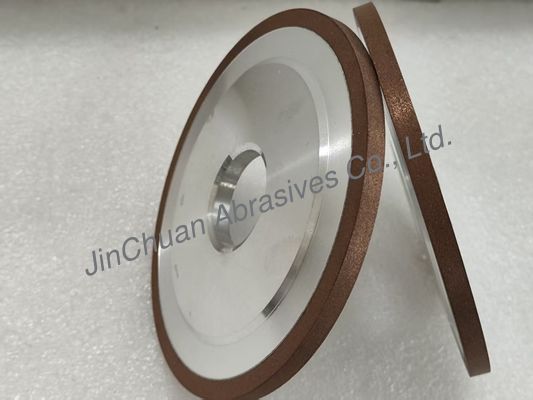

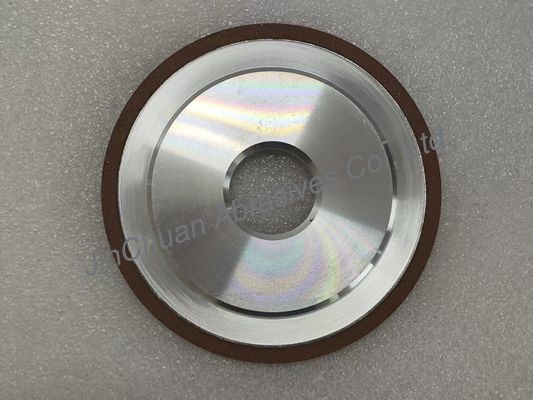

14A1 125*8*32*5*6mm Resin Bond Diamond Grinding Wheel Product Description

Product Name: Resin Bond Diamond Grinding Wheel

Product Overview:

Resin bond diamond grinding wheels are super-hard abrasive tools made by hot pressing diamond as the abrasive and resin as the binder. They are characterized by excellent heat-resistance , good grinding performance, elasticity,good finishing surface, good wear-resistance, not easy produce chips, high grinding efficiency, high machining accuracy, and long service life. These wheels are widely used for grinding and Sharpening Straight Knife Cutters For The Timber Machinery.

Product specification:

14A1: usually refers to a flat grinding wheel, concave on one side, used for external cylindrical or surface grinding.

125mm: grinding wheel outer diameter (D)

8mm: grinding wheel thickness (T)

32mm: inner hole diameter (H)

5mm: abrasive depth (X)

6mm: groove width (W)

Of course, we can also customize other sizes for you.

Applications:

Straight knife cutters used in:

Planers and jointers

Wood chippers

Veneer slicers

Band saw blades (carbide-tipped edges)

Typical Operations

Sharpening Dull Blades:

Restores sharp edges on carbide or high-speed steel (HSS) knives after wear from cutting hardwoods or composite materials.

Repairing Edge Damage:

Removes nicks, burrs, or micro-chips caused by knots, nails, or abrasive contaminants in timber.

Profile Grinding:

Maintains precise blade geometry (e.g., bevel angles of 25°–35°) for clean, tear-free wood surfaces.

Payment and Shipping:

We accept various payment terms, including T/T, L/C, WesternUnion, and PayPal. Our standard packaging is carton, but we can also customize the packaging based on your requirements. The Resin Bond Grinding Wheel comes in a sturdy cardboard box with foam padding to ensure safe transport and storage. Delivery time may vary depending on the destination, but typically takes between 5-10 business days.

Tips for increasing the cutting length:

Select the right grinding wheel specifications (grit size, concentration, bond type).

Optimize grinding parameters (speed, feed, cutting depth).

Use efficient cooling and lubrication systems.

Dress the grinding wheel regularly to keep it sharp.

Company introduction:

We are the professional manufacturer of resin bond diamond grinding wheels, equipped with advanced production facilities and testing instruments. Our products are known for their stable and reliable quality, earning the trust of our customers. We are committed to providing high-quality products and services. Welcome to inquire and purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!