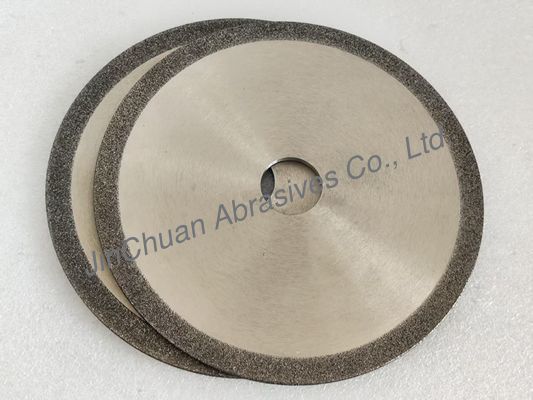

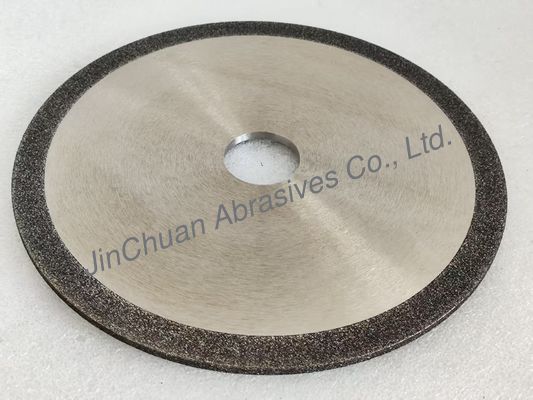

Electroplated CBN cutting wheel product description

Product name: Electroplated CBN cutting wheel

Product introduction:

Electroplated CBN cutting wheel is an ultra-thin cutting tool that uniformly consolidates a single layer of cubic boron nitride (CBN) abrasive on the surface of a metal substrate (usually steel or aluminum alloy) through an electrochemical deposition process. It is characterized by high abrasive protrusion and large chip space. It is designed for high-precision and high-efficiency cutting of hard and brittle materials and super-hard alloys (such as cemented carbide, ceramics, semiconductors, and high-temperature alloys). It is especially suitable for ultra-thin incisions and high surface quality requirements, such as precision electronic components, tool slotting, and brittle material processing.

Product features:

Ultra-thin high-precision cutting

The thickness can be as low as 0.1mm-2.0mm, and the incision is narrow, which is suitable for precision grooving and micro-parts separation.

The roughness of the cutting surface reaches Ra≤0.2μm, reducing the need for subsequent polishing.

Ultra-high cutting efficiency

The single-layer CBN abrasive directly participates in cutting, with small grinding force and fast cutting speed, which is suitable for high-speed automated equipment.

Open structure design, excellent heat dissipation, avoiding thermal damage to the workpiece.

Ready to use, no trimming

The electroplating process ensures that the abrasive is evenly distributed and sharp, and can be used directly without trimming, improving production efficiency.

Applicable to semiconductor workshops, such as without binder dust pollution.

Long life and flexible customization

The matrix has high rigidity and strong deformation resistance, and the life can reach 3-5 times that of resin grinding wheels.

Supports non-standard customization of special-shaped teeth, special apertures and outer diameters.

Specification

| Size |

Diameter |

Thickness |

Inner hole |

Abrasive width |

Grit |

| mm |

200 |

4.5 |

31.75

|

12.7 |

B60/70

|

Of course, We can customize the size according to your requirements

D: Diameter, T: Thickness, H: Inner hole, X: Abrasive width

Why choose electroplated CBN cutting wheel?

Ultra-thin design, almost zero material loss

Ready to use, suitable for automated production lines

Free cutting parameter optimization service

Packing and Shipping

Electroplated diamond grinding wheels are carefully packaged for shipment. Each wheel is placed in a plastic bag and wrapped in bubble wrap to prevent it from being scratched or damaged during transit. The package is then placed in a cardboard box and taped securely.

All orders are shipped via a reliable courier service. The tracking information and estimated delivery time are provided to customers once the order is shipped.

Company introduction

Zhengzhou Jinchuan Abrasive Abrasive Co., LTD. focuses on the research and development of electroplated superhard tools. It has a fully automatic electroplating production line and precision testing equipment. Its products have passed ISO 9001 and RoHS certification. We provide standardized and customized electroplated CBN cutting wheels, serving customers in the global electronics, tool, and aerospace industries, and are committed to providing customers with cost-effective precision cutting solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!