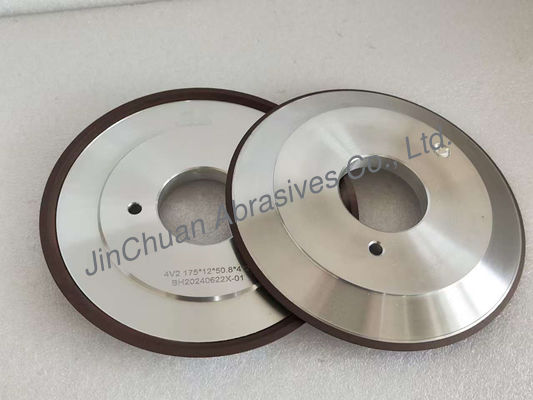

175mm Resin Bond Grinding Wheel for High-Hard Alloys and Non-Metallic Materials

Resin Bond is the most common choice in Diamond and CBN super-abrasive wheels. It forms a bond structure that keep the wheel sharp cutting, super surface finish, efficient grinding and less heat generating. The most important is that it is very cost effective. It is more competitive than Vitrified bond and Metal Bond. So it is broadly applied in the grinding industries.

Main Data Of Diamond Mounted Points

| Name |

Diamond Grinding wheel |

|

| Bond |

Resin bond , Vitrified bond , Metal bond &Electroplated |

Material |

Aluminium, Steel, etc |

| Abrasive |

Diamond and CBN |

Packing |

purple box, 1pcs /box |

| Size |

D:25mm-500mm T: 5mm-40mm H:10mm-127mm |

OEM/ODM |

Available |

| Type code |

1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. |

| Usage |

Mainly used for grinding , sharping and polishing . Widely used in the filed of PCD, CVD, PCBN ceramic, diamond processing, sapphire processing, stone , glass, ceramic, bearing, compressor , car engine processing industry, precision machining,etc |

| Sample Cost |

Depend on the size and quantity

|

Our Advantages

1. High grinding efficiency, relatively slow grinding wheel consumption and long grinding life.

2. Short production cycle, high removal rate and easy formation of complex surface.

3. Certain elasticity, which is conducive to improving the roughness of the workpiece surface, and is mainly used for fine grinding, semi-fine grinding, knife grinding, polishing and other processes.

4. Our company has professional technologies and equipment’s, which can form resin diamond grinding wheels with various complex surfaces.

Applications

Mainly used for grinding high-hard alloys, non-metallic materials, cutting hard and brittle hard alloys, non-metallic minerals, etc. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials and wear-resistant cast iron, stone, etc.Specially used to all kinds of sbrssives machine

high quality diamond raw material

good self-sharpening

excellent grinding effect

FAQ:

1.What material does your product use ?

Our product abrasives are diamond or CBN , which are electroplated, resin, vitrified, or metal bonded.

2.Do you offer samples ?

Yes, In order to start the new and happy cooperation , we can provide our customers sample for testing at the first order , we believe that you will be satisified with our product quality.

3. Can we go to visit your factory ?

Of course yes , welcome to visit our factory , you can see our production capacity and technoly. Remeber to contact our sales first before your visit.

4.How can you guarantee the quality ?

We examine the quality 3 times before strat the delivery , first : pre-production , second : post-production , third : before delivery . So do not worry about this.

NOTE: If you do not find the product you want in this website, contact us first, we can design and produce any specification of grinding wheel head according to your requirement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!