Description

Electroplated CBN grinding wheel has higher material cutting rate and lighter cutting, it can reduce the heat damage to the metal surface of the workpiece

Electroplating wheel can greatly reduce or eliminate the time of adjusting, replacing and dressing the wheel in the grinding process

Feel free to contact me if you need them, we can send them to u immediately.

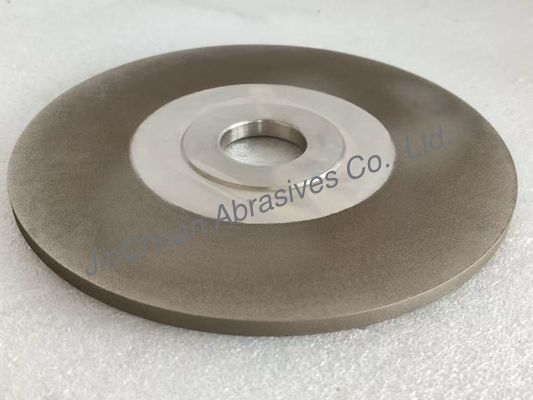

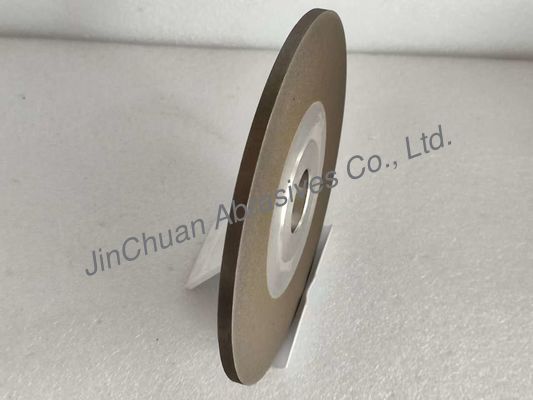

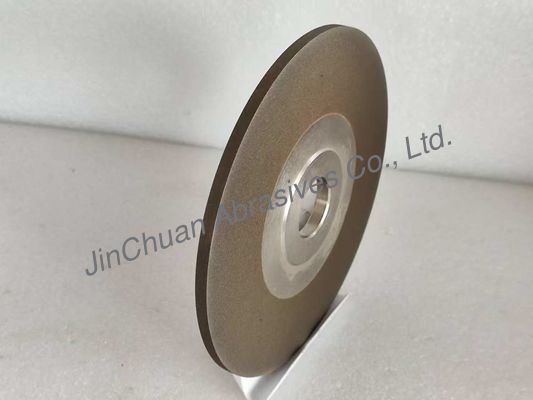

Specification

| Size |

Diameter |

Thickness |

Inner hole |

Abrasive width |

Grit |

| mm |

180 |

8 |

31.75

|

40 |

B400

|

Of course, We can customize the size according to your requirements

Benefit

1,No need to trim, easy to use

2,Strong wear resistance and long service life,

3,CBN grinding wheel dressing cycle is long, dressing amount is small, replacement time is long; Long service cycle, high grinding ratio, can

4,obtain better economy, shape retention in use, no need to change the wheel and dressing wheel often, save labor hours, improve labor conditions, is conducive to processing operation.

Related applications

Company introduction

Zhengzhou Jinchuan abrasive abrasive co., LTD. Is committed to providing the most advanced diamond and cubic boron nitride products.

We have experienced engineers and technical experts, professional industrial knowledge and technical services to help customers find the best solutions.

Our sophisticated production equipment and advanced testing equipment, so that our products good performance.Constantly pursue new technology and continuous improvement.

We look forward to our cooperation.

NOTE: If you do not find the product you want in this website, contact us first, we can design and produce any specification of grinding wheel according to your requirement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!