Product Description:

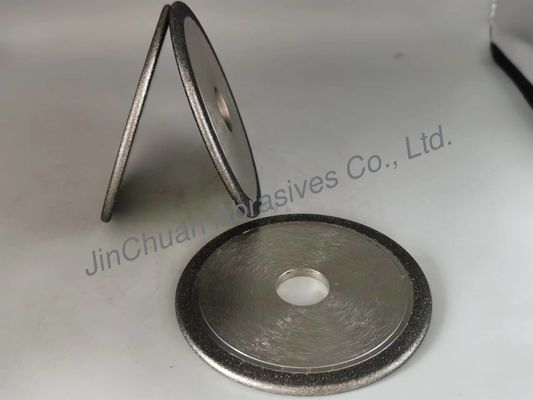

Electroplated CBN Grinding Wheels are a special type of abrasive wheels specifically designed for precision grinding and finishing applications. Featuring a unique combination of B126 and D100, the Electroplated CBN Grinding Wheels provide a superior grinding performance even on the toughest materials. With its custom edge type and 4.5mm thickness, the grinding wheels are capable of achieving excellent finishing results with a diamond width of 7.6mm. For added convenience, the Electroplated CBN Grinding Wheels come in a carton packaging, making it easy to store and transport.

Features:

- Product Name: Electroplated CBN Grinding Wheels

- Shape: 1F1

- Edge Type: Customized

- Grit: B80/100

- Body: Steel

- Thickness: 4.5mm

Applications:

JC Electroplated CBN Grinding Wheels is ideal for grinding and finishing of various metals, especially for difficult-to-grind materials such as hardened steel, stainless steel, and superalloys. It is available in Model 1F1, with a diameter of 105 mm, and Grit B80/100. It is manufactured with a steel body and a CBN edge, which can be customized according to your needs. It is perfect for cutting, grinding, and polishing operations, and can be used for roughing and finishing operations in a wide range of industries such as aerospace, automotive, and medical. This grinding wheel has superior edge retention and heat resistance, making it an ideal choice for precision grinding applications.

Customization:

We provide custom-made Electroplated CBN Grinding Wheels with the brand name JC. Our products feature a Hole Diameter of 22, an Edge Type that can be Customized and a Shape of 1F1. Our products are electroplated and packaged in a Carton.

Support and Services:

Electroplated CBN Grinding Wheels Technical Support and Service

We provide technical support and service for our electroplated CBN grinding wheels. Our team of experienced professionals is available to help you with installation, use, and maintenance of the grinding wheel. We also provide troubleshooting advice and product information.

We are committed to helping you get the most out of our products. If you have any questions or concerns, please do not hesitate to contact us. We are here to assist you and provide the best possible service.

FAQ:

Electroplated CBN Grinding Wheels are produced by JC with the model number 1F1, which are made in China. They are used for grinding and cutting hard materials, such as hardened steels, carbides, composites, etc.

Q:What are the benefits of using Electroplated CBN Grinding Wheels? A:

Electroplated CBN Grinding Wheels offer high removal rates, increased precision, and an extended wheel life due to their high strength and wear resistance. They also allow for a smooth surface finish and are able to grind hard materials at high speed.

Q:What materials can Electroplated CBN Grinding Wheels be used for? A:

Electroplated CBN Grinding Wheels can be used for grinding and cutting hard materials, such as hardened steels, carbides, composites, etc.

Q:How do Electroplated CBN Grinding Wheels work? A:

Electroplated CBN Grinding Wheels are designed to be used in a rotary grinding motion. They are coated with a layer of abrasive on the circumference, which helps to grind and cut hard materials such as hardened steels, carbides, composites, etc.

Q:What are the advantages of using Electroplated CBN Grinding Wheels? A:

The advantages of using Electroplated CBN Grinding Wheels are that they offer high removal rates, increased precision, and an extended wheel life due to their high strength and wear resistance. They also allow for a smooth surface finish and are able to grind hard materials at high speed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!