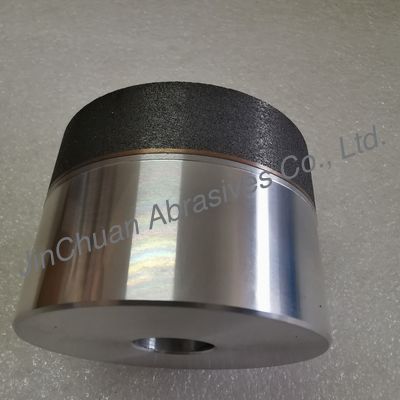

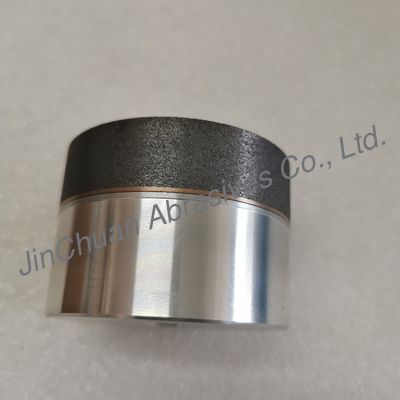

Product Description:

"Hbrid grinding wheel" is a technical term that generally refers to a hybrid grinding wheel.

Simply put, an Hbrid grinding wheel is a high-performance abrasive tool made by combining two or more different types of abrasives (resin, ceramic, and metal-bonded) within a single grinding wheel design.

Traditional grinding wheels typically use only one type of primary abrasive (e.g., all corundum or all silicon carbide). The design philosophy of hybrid grinding wheels is to "compensate for each other's weaknesses," scientifically proportioning and combining abrasives with different properties to achieve comprehensive superior performance that cannot be achieved with a single abrasive.

Features:

Hbrid grinding wheels represent a significant development direction in modern abrasive technology. They no longer rely on the properties of a single abrasive, but rather integrate the advantages of different abrasives through a "teamwork" approach, achieving:

- Faster cutting speeds

- Longer service life

- Better machining quality

- Wideer applicability

Technical Parameters:

| Abrasives |

CBN |

| Package |

one in box |

| Diameter |

75mm |

| Thickness |

52mm |

| Base Body |

Aluminum |

| Inner hole |

20mm |

| Abrasive width |

10mm |

| Grit Size |

B126 |

| Country Of Origin |

China |

| Packing |

One in box |

| Hs Code |

6804221000 |

| Sharp |

Cup sharp |

| Bond type |

Hybrit |

Applications:

Typical abrasive combinations in hybrid grinding wheels include:

1. Resin + Metal Bond: This is the most commonly used combination.

2. Ceramic + Metal Bond: This is a commonly used combination nowadays.

3. Resin + Ceramic + Metal Bond: This is the most durable and highest-performing combination.

CBN + Hybrit: When machining superhard materials, CBN (cubic boron nitride) is mixed with other auxiliary abrasives to optimize its performance in machining specific materials.

FAQ:

Q1: Do you offer samples ?

A1: We sincerely want to cooperate with you, so we will provide samples for you to test.

Q2: What is the minimum order quantity and unit price?

A2: Most of our products are custom-made, so the minimum order quantity and unit price vary depending on the product.

Q3: How do you ship your products?

A3: We ship via international express such as FedEx, UPS, TNT, EMS, DHL, SF Express, etc. For large orders, we can choose to ship by sea. You can choose to pick up the goods at the port closest to you.

Q4: What materials are used in your products?

A4: Our abrasives primarily use diamond and CBN. We can recommend a suitable bond based on your needs, including electroplating, resin, ceramic, and metal bonds.

Q5: Can you provide different types of packaging according to customer needs?

A5: Yes, we can label and package according to your requirements.

Q6: How can you guarantee the quality ?

A6: We have a complete quality management system, strictly manage quality during the production process, and provide one-to-one after-sales service.

Q7: How long do you expect to deliver?

A7: After you place your order, pay, and confirm your drawings, we'll arrange production. Delivery is expected to take approximately 7-10 days.

Q8: Can I ship through my own freight forwarder? Are customers allowed to use their own freight forwarder for shipping?

A8: Yes, If you have your own freight forwarder, you can come to pick up the goods. Or we can ship to your freight forwarder.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!