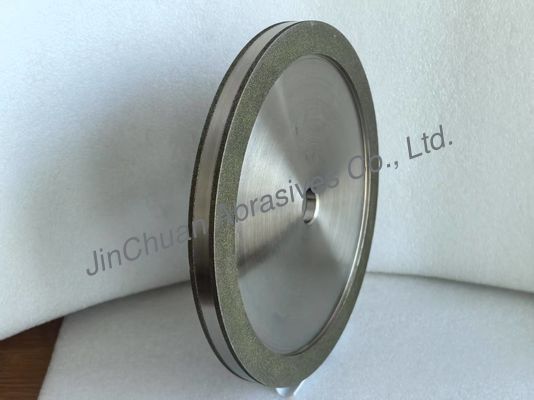

9A3 Electroplated Diamond Grinding Wheels for Precision Grinding and Sharpening Disc

Product Information Of Diamond wheel for grinding and sharpening

An electroplated bonded diamond grinding wheel is a type of abrasive tool where diamond grains are bonded to a metal wheel using an electroplating process. This type of wheel is known for its high grinding efficiency, long lifespan, and ability to process hard and brittle materials like ceramics, glass, carbide, and advanced composites.

Electroplated Bonding:

- Diamond particles are electrodeposited onto a metal (usually nickel or nickel-cobalt) substrate, forming a single-layer or multi-layer abrasive surface.

- The bond strength is high, ensuring minimal grain pull-out during grinding.

Electroplated diamond grinding wheels are ideal for high-precision applications where minimal wheel wear and consistent performance are critical. They are widely used in industries like optics, aerospace, and tool manufacturing. For heavy material removal, sintered metal-bonded wheels may be more suitable.

Main Data Of Electroplated diamond grinding and sharpening wheels

| Technical Parameter |

Details |

| Size |

228.5*16.5*22.22mm |

| Hs Code |

6804211000 |

| Base Body |

Steel |

| Shape |

9A3 |

| Material |

Diamond, Steel Basebody |

| Packing |

Standard Exported Carton Packing |

| Package |

Color Box |

| Country Of Origin |

China |

| Application |

Grinding and Sharpening

|

Advantages:

✔ High grinding efficiency & material removal rate.

✔ Long service life with consistent performance.

✔ Suitable for dry or wet grinding.

✔ Can be customized with different grit sizes (coarse to fine).

If you need to customize, please provide the following information:

1. Dimensions, including outer diameter, aperture, thickness, width and thickness of abrasive layer;

2. Abrasive, abrasive sand particle and concentration;

3. Adhesive;

4. Wheel application;

5. Pictures and drawings of wheels;

We can then design and quote for you

FAQ:

1.What material does your product use ?

Our product abrasives are diamond or CBN , which are electroplated, resin, vitrified, or metal bonded.

2.Do you offer samples ?

Yes, In order to start the new and happy cooperation , we can provide our customers sample for testing at the first order , we believe that you will be satisified with our product quality.

3. Can we go to visit your factory ?

Of course yes , welcome to visit our factory , you can see our production capacity and technoly. Remeber to contact our sales first before your visit.

4.How can you guarantee the quality ?

We examine the quality 3 times before strat the delivery , first : pre-production , second : post-production , third : before delivery . So do not worry about this.

NOTE: If you do not find the product you want in this website, contact us first, we can design and produce any specification of grinding wheels as customer's requirement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!