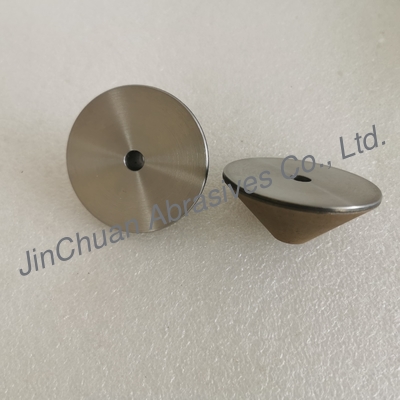

The electroplated diamond grinding wheel for grinding car rearview mirrors is a high-precision tool, mainly used for precision machining of rearview mirror molds or glass edges.

1. Structure and Principle

Material: The wheel is usually made of steel to provide structural support.

Electroplating layer: Diamond abrasive grains are firmly fixed on the surface of the matrix through electroplating processes such as nickel plating. The diamond particles are evenly distributed to form a high-hardness cutting layer.

Diamond particles: Different particle sizes are selected according to processing requirements, and the common particle size is 1000#.

2. Features and Advantages

High hardness and wear resistance: Diamond (Mohs hardness 10) can efficiently dress various types tempered glass.

Long life: The electroplating process makes the diamond particles have high bonding strength, slow wear, and significantly longer service life than traditional dressing tools.

3. Application

Rearview mirror mold processing: polishing the metal or ceramic mold surface to ensure mirror reflection effect.

Glass edge chamfering/grinding: used for precision trimming of rearview mirror glass to avoid edge collapse.

Repair and maintenance: repair scratched or worn rearview mirror surface (need to use coolant to prevent thermal cracking).

4.Company Profile

We are a superhard material manufacturer in China with 16 years of export experience in this field. Our main products are CBN and diamond grinding wheels, and the bonding agents are mainly electroplating, resin, ceramic, and metal. If you need , please feel free to contact me ,we can customize wheels for you.

5.If you need to customize, please provide the following information

1). Dimensions, including outer diameter, aperture, thickness, width and thickness of abrasive layer;

2). Abrasive, abrasive sand particle and concentration;

3). Wheel application;

4). Pictures and drawings of wheels;

We will give you a suitable quotation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!