CBN Sharpening Wheels Cubic Boron Nitride Material With Long Service Life

-

Highlight

cbn chainsaw grinding wheels

,cbn abrasive wheels

-

Carten ColourPurple

-

ColourBlack

-

Size8 Inches

-

MaterialCubic Boron Nitride

-

Inner Hole32mm

-

GritB126 / B151 / B251 And So On

-

Place of OriginCHINA

-

Brand NameJC

-

CertificationISO9001:2015&ISOCE16949

-

Model NumberGrinding wheels 7/39.5

-

Minimum Order Quantity5 pcs

-

PriceNegotiable

-

Packaging DetailsPurple color box

-

Delivery TimeAT the moment

-

Payment TermsL/C, T/T

-

Supply Ability1000 pcs per month

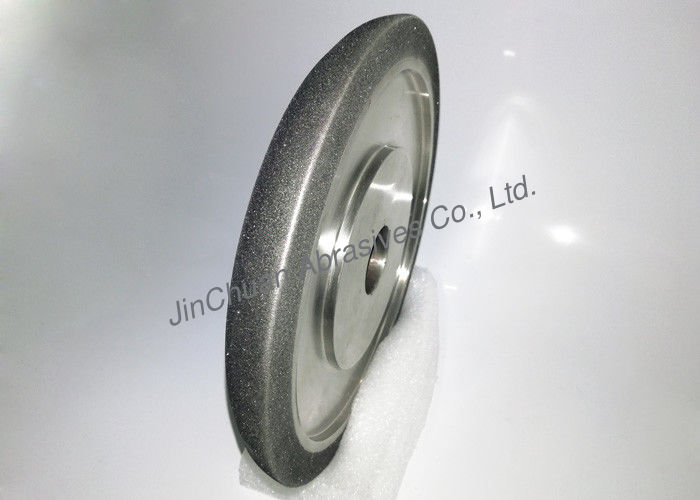

CBN Sharpening Wheels Cubic Boron Nitride Material With Long Service Life

8 Inch 7/39.5 CBN Sharpening Grinding Wheels With 65,00 meter working life

CBN SHARPENING WHEELS

Description

Cubic boron nitride is not easy to react with iron group elements, so it is very suitable for grinding all kinds of high speed steel, tool steel, high alloy hardened steel, chromium steel, nickel alloy, powder metallurgy steel and high temperature alloy with high temperature, high hardness and low heat conductivity.

![]()

|

Size |

Inside Diameter(D) | Thickness(t) | Hole(H) | Angle(r/R) | Grit Size |

| 8" | 203mm | 22.23mm(7/8") |

32mm |

7/39.5 |

B126 B151 B251 |

Of course, we can also produce products of other sizes

Advantage

We can make thousands of wheels one month, and our products are always in stock .So you can rest assured of the delivery date of our products

Benefit

Our electroplated CBN grinding wheel has a special weight reduction design, which can reduce the weight of the grinding wheel, not only in the use of more light, but also can reduce the cost of transportation

CBN grinding wheel can obtain high dimensional accuracy and low surface roughness, machining surface is not easy to produce cracks and burns, residual stress is small.

Machining surface quality has been improved, generally no cracks, not easy to burn, and can obtain residual compressive stress, significantly improve the fatigue strength of the workpiece division