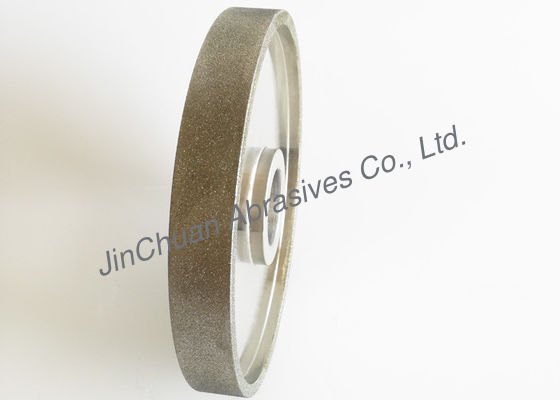

Diamond Sharpening Parallel Wheels Used To Abrasives Knifes

Specification

|

Size

|

Diameter |

Thickness |

Inner Hole |

Grit Size |

| 5'' |

127mm |

22.23mm |

12.7mm |

B251

|

Diamond grinding wheels are electroplated with a single layer of durable nickel coated.

Electroplating product have many advantages compeare other applications. It creates a more aggressive bond over other applications and will hold a form longer. It also performs a higher stock removal rate and will last several months.

Used

perfect for sharpening hard material .

Can use in the processing high rigidity nonmetallic materials,such as ceramics, glass, mold, gem and so on materials, with characteristics of keep good precision, cuts sharply, high efficiency's ect.

Advantage

1.Diamond grits can be customized.

2.long service time

3.High quality

4.Competitive Price

5.Customize according you drawing

6.with profesional technical team and prodution line , can produce amounts of high quality products in a short time .

Benefit

Quality: as we are manufacturer of diamond powders which is raw material of diamond tools, we can assure the quality from original material. And can control the quality of all our tools as we have a professional and strict QC team.

Price: as a manufacturer, we can save production cost for customer.

Service: we have professional sales team and engineering team, can reply you at the first time, and solve problems for you soon.

Product picture

Company profile

Zhengzhou Jinchuan abrasive abrasive co., LTD. Is committed to providing the most advanced diamond and cubic boron nitride products.

We have experienced engineers and technical experts, professional industrial knowledge and technical services to help customers find the best solutions.

Our sophisticated production equipment and advanced testing equipment, so that our products good performance.Constantly pursue new technology and continuous improvement.

We look forward to our cooperation

Why choose us?

1.We are factory production, the price is favorable

2.Experienced in making sure that the cutting edge is sharp and the cutting surface is smooth and wear resistant.

3.Using mirror grinding technology, the production of large space design

4.Fast chip removal speed, high cutting efficiency, dynamic balance test

5.We have regular sizes and can also be customized according to the drawings

Looking forward to your inquiry

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!