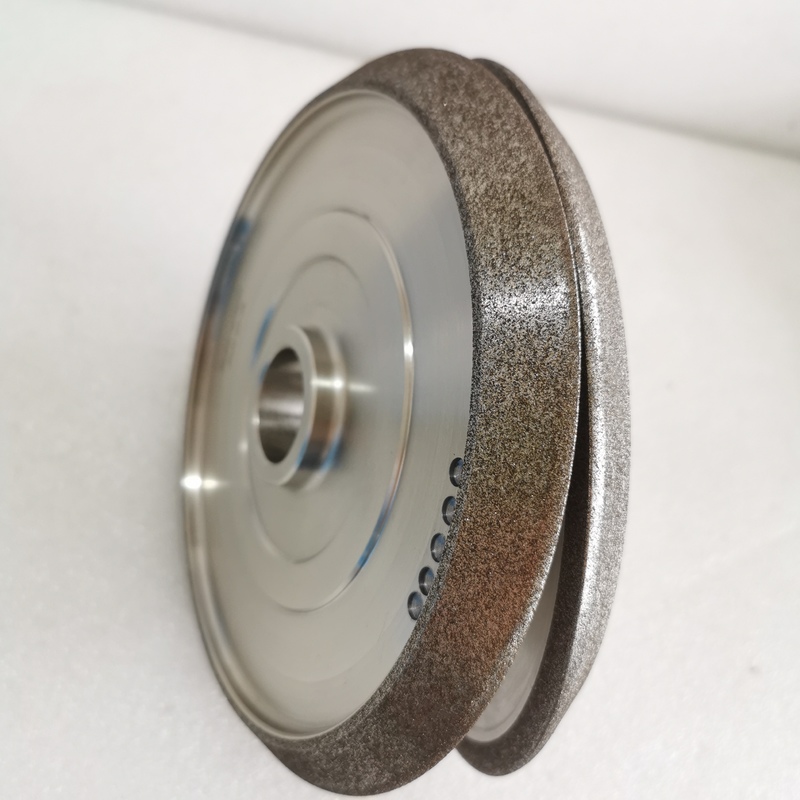

Customizable 8" 4TPI Electroplated CBN Grinding Wheels For Personalized Grinding Needs

-

Highlight

8 inch electroplated CBN wheel

,customizable CBN grinding wheel

,4TPI electroplated grinding wheel

-

Thickness22.23mm

-

ApplicationSharpening Band Saw Blades

-

Base BodySteel

-

Grit SizeB151, B181, B213

-

Country Of OriginChina

-

PackageOne In Paperbox

-

Profile10/30 , 9/29

-

ShapeCylindrical

-

Diameter203mm

-

Inner Hole31.75mm

-

BondElectroplated

-

DrawingAs U Reqirement

-

Cbn ColorAmber , Black

-

Hs Code6804221000

-

BalanceDynamic Balance

-

DurabilityLong-lasting

-

Wheel ShapeCylindrical

-

Place of OriginChina

-

Brand NameJC

-

CertificationISO

-

Model NumberCustomized

-

Minimum Order Quantity2 pieces

-

PriceNegotiable

-

Packaging DetailsOne in paperbox

-

Delivery Time7 working days

-

Payment TermsTT, Western Union, Paypal

-

Supply Ability10000/month

Customizable 8" 4TPI Electroplated CBN Grinding Wheels For Personalized Grinding Needs

Product Description:

Superabrasive is a term used to describe Diamond and CBN (Cubic Boron Nitride). Diamond is the hardest substance on the Knoop Hardness Scale and the only abrasive capable of grinding ultra-hard materials. CBN is a new type of artificially synthesized material developed in the 1950s, with a hardness second only to diamond . They can both applied. Althougth CBN and Diamond are both superabrasive, the areas of use vary consid-erably by material. In general, diamond is used for grinding non-metallic hard and brittle materials, while CBN is used to grind ferrous materials.

Electroplated CBN band saw grinding wheels are superhard grinding wheels used to sharpen and dress band saw blades by electroplating cubic boron nitride abrasive particles firmly adhered to the surface of a metal substrate.

CBN: Cubic boron nitride, second only to diamond in hardness, is specifically designed for machining ferrous metals (such as high-speed steel).Electroplating: A manufacturing process that "locks" the abrasive particles onto the substrate through metal electrodeposition (usually nickel or a nickel alloy).Essentially, it is a tool with extremely strong cutting capabilities, uniformly distributed CBN abrasive grains on a metal substrate, far exceeding the performance of traditional grinding wheels.

CBN grinding wheels can be mainly classified into metal-bonded, ceramic-bonded, and resin-bonded types according to the type of bond. With the development of superhard materials tool technology, the objects that can be machined include almost all known materials, which greatly improves the processing efficiency and quality in various precision machining fields, especially as an important part of advanced manufacturing technologies such as high-speed, precision, CNC, and micro-machining.

Features:

- Exceptional sharpness and high efficiency

- Superior shape retention and precision

- Easy to operate, requiring no dressing

- Strong adhesion, able to withstand harsh grinding conditions

- Application: Bandsaw Blade Sharpening

- Wide range of applications

Technical Parameters:

| Material | Cubic Boron Nitride, Steel Basebody |

| Thickness | 22.23mm |

| Base Body | Steel |

| Profile | 10/30 , 9/29 |

| Grit Size | B151 B181 B213 |

| Country Of Origin | China |

| Packing | Standard Exported Carton Packing |

| Hs Code | 6804221000 |

| Application | Bandsaw Blade Sharpening |

| Balance | Dynamic balance |

| Durability | Long-lasting |

| Wheel Shape | Cylindrical |

Applications:

This grinding wheel is specifically designed for high-demand, high-efficiency band saw sharpening, and is particularly suitable for:

High-precision, high-volume band saw blade manufacturers.

Automated saw sharpening centers with extremely high requirements for tooth quality and consistency.

Sharpening modern high-performance bimetallic band saw blades and tungsten carbide coated band saw blades.

Precision sawing service providers requiring minimal burns and extended blade life.

![]()

![]()

![]()