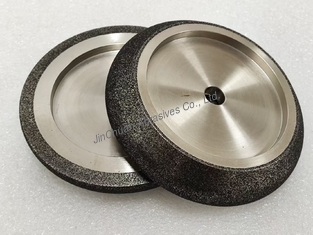

Customized 127*22.7*12.7mm WM 10/30 B251 Electroplated CBN Grinding Wheel

-

Highlight

B251 Electroplated CBN Grinding Wheel

,Customized Electroplated CBN Grinding Wheel

-

ColourBlack

-

Size5 Inches

-

Inner Hole12.7mm

-

GritB251

-

Bond TypeElectroplated

-

ApplicationGrinding Of Hardened Steels, High Speed Steels, And Super Alloys

-

Abrasive MaterialCubic Boron Nitride (CBN)

-

Packing1pcs/paper Box

-

DrawingAs U Reqirement

-

Material45# Steel

-

ShapeRound

-

HS Code6804221000

-

Thickness22.7mm

-

Place of OriginCHINA

-

Brand NameJC

-

CertificationISO

-

Model NumberWOOD MIZER 5" 10/30

-

Minimum Order Quantity5 pcs

-

PriceNegotiable

-

Packaging DetailsCardboard Box

-

Delivery Time5-10 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability10000 pcs per week

Customized 127*22.7*12.7mm WM 10/30 B251 Electroplated CBN Grinding Wheel

Basic structure and composition

CBN abrasive layer:

High-purity cubic boron nitride (CBN) particles are fixed on the surface of the metal substrate through an electroplating process.

Substrate material:

High-strength 45# steel or aluminum alloy is used.

Binder:

Electroplated nickel is used as a binder.

Advantages:

1,Excellent high temperature performance

2,Strong antioxidant capacity

3,Sharp, Fast grinding

4,Long life, Much longer life than traditional abrasive wheels

5,No dust coming out when sharpening and grinding

| Size | Diameter | TS | Inner hole | W/M | Grit |

| 5" | 127mm | 22.7mm |

12.7mm |

10/30 |

B251 |

Of course, We can customize the size according to your requirements

Available Wheel Profiles:

* 10/30 - Mostly Used Universal Grinding Wheel Profile

* 9/29 - Perfectly Prepares Band Saws For Winter Time Cutting, Or Cutting Hard Wood

* 13/29 - Wheel Profile Which Prepares Band Saws For Soft Wood Cutting

* 4/32 - Wheel Profile Which Can Prepare Band Saws For Very Frozen And Very Hard Wood Cutting

* 7/34 The CBN Wheels Profile Is Recommended For Hardwood

Company introduction:

Zhengzhou Jinchuan abrasive abrasive co., LTD. Is committed to providing the most advanced diamond and cubic boron nitride products.We have experienced engineers and technical experts, professional industrial knowledge and technical services to help customers find the best solutions.

Looking forward to cooperate!