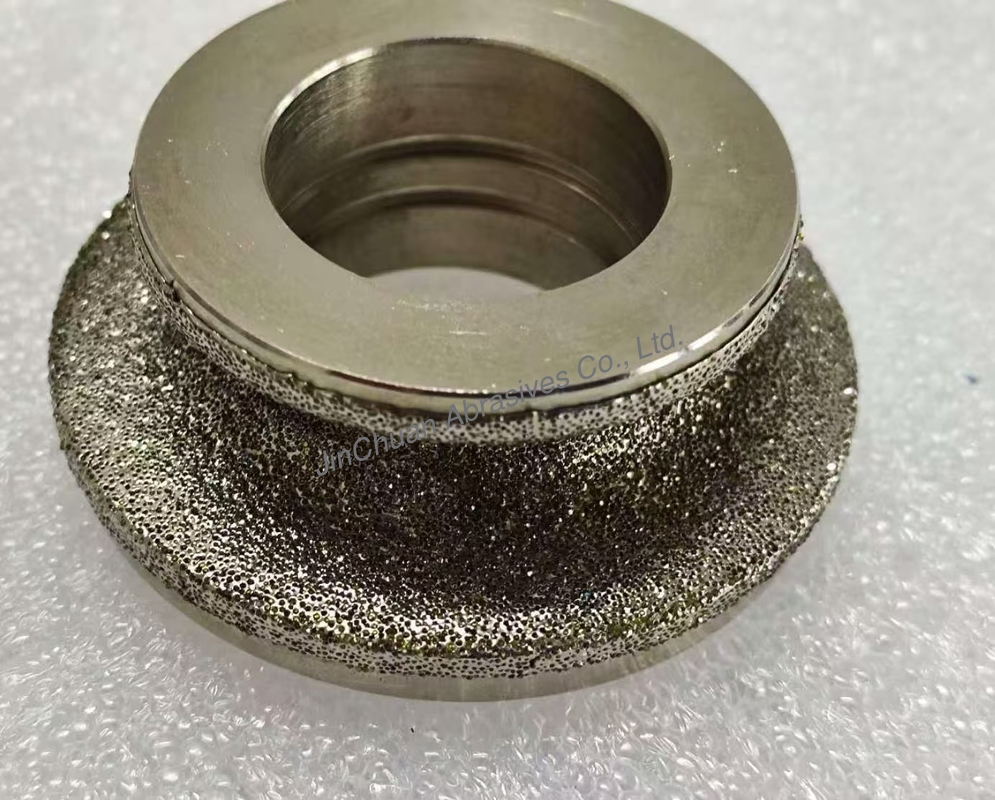

Electroplated Diamond Dressing Wheels For Machining Tungsten Carbide And Hardened Steel Dies

-

Highlight

Electroplated Diamond Dressing Wheel

,High Precision Electroplated Diamond Dressing Wheel

-

SpecificationMake According To U Drawing Size

-

PackageOne In Paperbox

-

Body MaterialSteel

-

MaterialBase Material

-

AbrasivesDiamond

-

ProcessElectroplated

-

Place of OriginZhengzhou,China

-

Brand NameJC

-

CertificationISO

-

Model NumberJC-customized

-

Minimum Order Quantity10pieces

-

PriceExw

-

Packaging DetailsExport Packaging

-

Delivery Time5-8 workdays

-

Payment TermsWestern Union, T/T,PayPal

-

Supply Ability10000pcs/month

Electroplated Diamond Dressing Wheels For Machining Tungsten Carbide And Hardened Steel Dies

Product Description:

Electroplating: Using appropriate methods to finish the processed or manufactured parts ensures their longer durability. This is also crucial for the function of certain high-performance applications. Electroplating is a popular finishing method that can customize mechanical properties and appearance with suitable plated metals.

Product Applications:

Processing objects:

Stone, ceramic, glass, jade

Why choose our company?

1. Diamond particles are made of grade 1 corundum, which is not easy to wear

2. Sharp and easy to use, smooth grinding, fast peeling, sharp

3. Complete specifications, can meet all kinds of grinding and engraving needs

Questions and Answers:

1.Q: Can I get some samples or make customization according to the drawings and requirements?

Yes, sample orders are welcome

2.Q: Are there any items in stock?

A: For most items, we have stocks and will arrange timely delivery.

3.Q: Can I use my own logo?

A: Yes, customized logo and design can be produced in bulk, but we need authorization.

4.Q: What is the supply capacity of this diamond wheel?

A: Supply 10000 pieces per month.

5.Q: What is the payment method?

A: We can accept payment by T/T, Western Union, PayPal, payment link.

6.Q: What are your shipping methods?

A: UPS, DHL, Fedex, EMS, etc.