-

Highlight

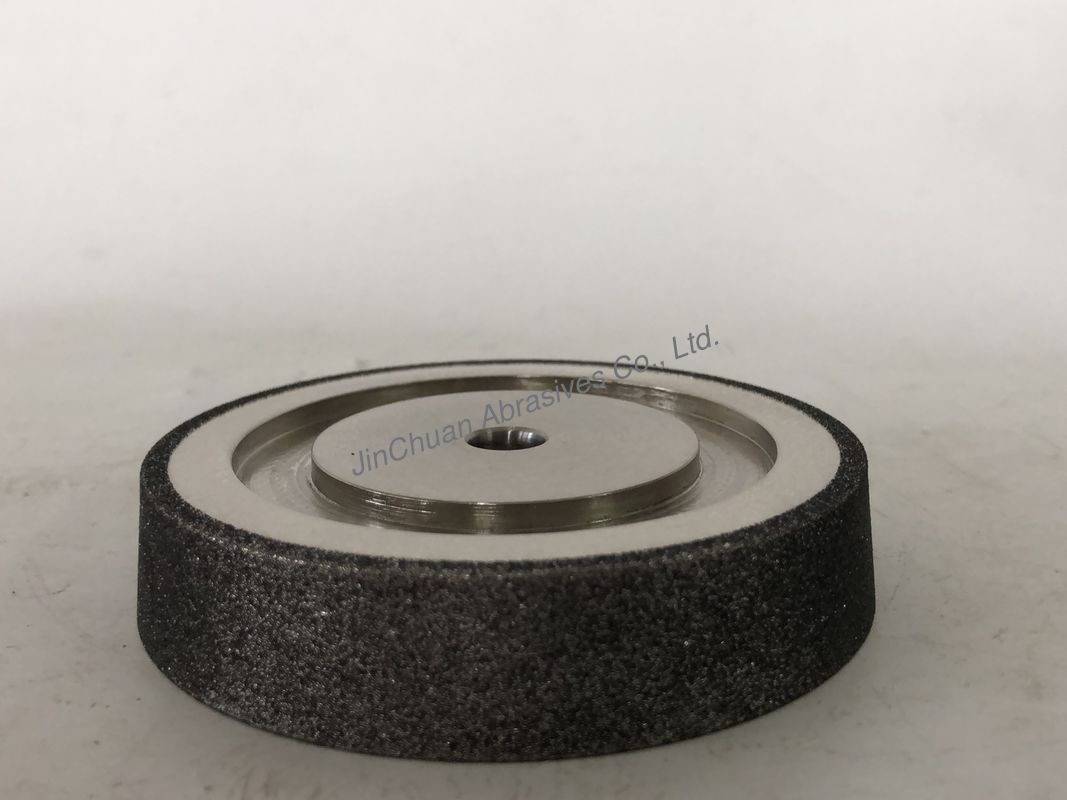

Alloy CBN Grinding Wheels

,Oblateness CBN Grinding Wheels

-

ShapeOblateness

-

Size127.1*13*30

-

AbrasiveCbn

-

HardnessAlloy Materials

-

Viscosity100%

-

Bonding AgentElectroplated

-

Place of OriginChina

-

Brand NameJc

-

CertificationISO9001:2015&ISOCE16949

-

Minimum Order Quantity5pcs

-

PriceNegotiable

-

Packaging Detailspurple box

-

Delivery Time30days

-

Payment Terms100%, T/T

-

Supply AbilityCustomer order decision

5"Alloy Oblateness Electroplated CBN Grinding Wheels

Electroplated CBN Grinding Wheels

Introduction:The forming process of grinding wheel is simple, the production cost is low, and the forming process is simple, but it has only one layer of coating, which cannot be corrected. It is suitable for small batch machining and geometric complex forming grinding and is used as dressing roller.

size:

| D | H | T | The Angle | Particle size |

| 127.1mm | 13mm | 30mm | 60 | 100/120 |

Advantages:

1. CBN is a synthetic, second only to diamond in hardness, and therefore has better cutting ability and sharpness.

2. CBN can withstand temperatures of 1250-1350 degrees Celsius, higher than the heat resistance of diamond of 800 degrees Celsius.

When grinding and cutting iron materials, there will be no sticky chip phenomenon, and it is the most ideal grinding wheel for quenched steel, high vanadium high speed steel, aluminum high speed steel and other metal materials that are sensitive to grinding temperature.

3. Good wear resistance and long life.The grinding ratio of CBN wheel can reach 3500-5500, which is 100 times higher than ordinary corundum wheel and 3-5 times higher than diamond wheel.

4. With sharp grinding, long dressing cycle and long service cycle of CBN grinding wheel, it can achieve better economy, maintain good shape in use, and it is unnecessary to change and dress the grinding wheel frequently, thus saving working hours.

![]()